Anti Corrosion Technical Services Limited | ISO9001:2015 & STOWTT Certified

Leading Petrochemical Service Company of Trinidad and Tobago

Anti Corrosion Technical Services Limited | ISO9001:2015 & STOWTT Certified

Leading Petrochemical Service Company of Trinidad and Tobago

At Anti- Corrosion we offer a wide range of products that are differentiated from those that are often seen in the industry. This strategy has served us well as we continue to study the best materials to incorporate into our bespoke problem solving techniques. Below are some of these sought after products

Contact us

Chesterton's ARC coating provides superior performance against erosion, corrosion, abrasion, and chemical attack. Industry faces adverse environmental conditions that attack components and structures and result in compromised plant reliability and safety and lost profits. When cementitious or metallic surfaces are subject to aggressive industrial application environments you can rely on Chesterton's 100% solids, low VOC protective linings.

Concrete Composite Systems

ARC Concrete Composite Systems (CCS) repair, rebuild and protect all concrete structures from abrasive, corrosive and chemically aggressive environments.

Metal Composite Systems

ARC Metal Composite Systems (MCS) repair, rebuild and protect all types of industrial process equipment and structures from abrasive, corrosive and chemically aggressive environments.

http://www.chesterton.com

Carbon Fiber, Fiberglass & Aramid Composite Reinforcing Systems NRI's core business focus is in the development and manufacture of moisture-curable composites for the retrofit and reinforcing of defects and anomalies in pipelines as well as civil structures. With help from NRI, our clients can restore and protect their assets that are degrading or in jeopardy of failure. NRI provides the perfect solutions for in-service repairs, allowing its clients to continue operations in a quick and reliable manner. Clients save millions in costs, as well as in lost revenues, by enabling them to repair and reinforce to original design specification out in the field. NRI products are used internationally and serve a broad range of markets including: oil and gas, industrial, marine, municipalities, mining, construction, and utilities.

-Viper-Skin™

-Viper-Skin™http://www.neptuneresearch.com

The Visco-Elastic Coating & Sealant Solution

STOPAQ supplies a wide range of green visco-elastic solution to protect assets from corrosion and water ingress. Our visco-elastic coatings & sealants are used in many versatile applications ranging from pipelines to sub-sea piles and from rail to cable joint protection and are marketed world-wide as such. The applications for the STOPAQ® visco-elastic product systems range from onshore & offshore, field & factory applied to sub-sea and above ground in the most extreme climates. Our Product Range can be divided into three main product groups.

-Oil & Gas (Corrosion Prevention products)

-Waterproofing (Sealing products)

-Insulation

http://stopaq.com

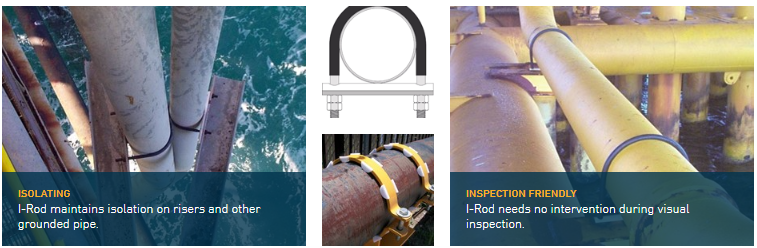

Deepwater designs and manufactures cathodic protection systems for offshore and marine assets, specializing in the development of innovative retrofit technology for aging assets in need of life extension.

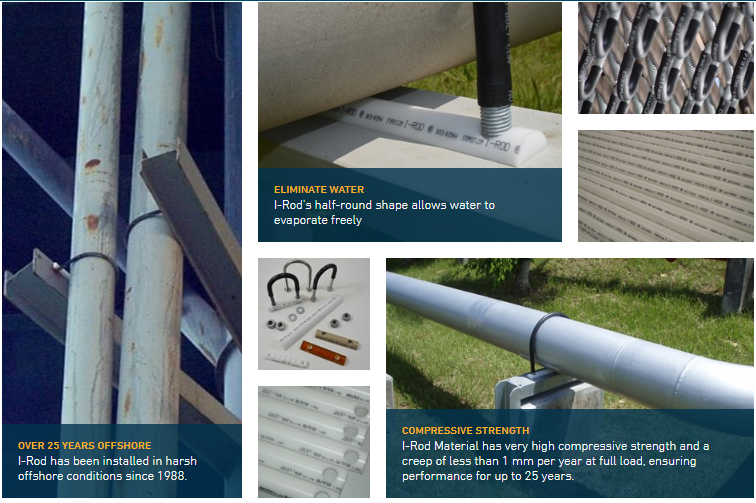

I-Rod is a durable thermoplastic, extruded and cut into a half round rod. It is the key component in all of Deepwater's I-Rod brand pipe supports. It is available in 10 foot lengths, or cut-and-drilled for use with standard size pipe U-bolts. There are three different diameter sizes for I-Rod (0.75 in, 1 in, and 1.5 in) as well as a high-temperature version for process piping that operates above 200 °F.

Designed by corrosion engineers, the Nu-Bolt assembly combines the half round I-Rod support with a modified pipe U-Bolt. A variety of corrosion resistant treatments provide reliable, long term service in the severe operating environments associated with offshore oil and gas production and coastal process facilities.

For over 20 years, Milamar Coatings, L.L.C. has been formulating high performance resinous floor coatings, as well as lining and wall coatings installed by our network of certified applicators throughout the United States and countries around the world. You will recognize these trusted brands: PolyMax, International Coatings, Protective Floorings & Linings, SUPERCOAT, & SUPERCOAT DecoEffects.